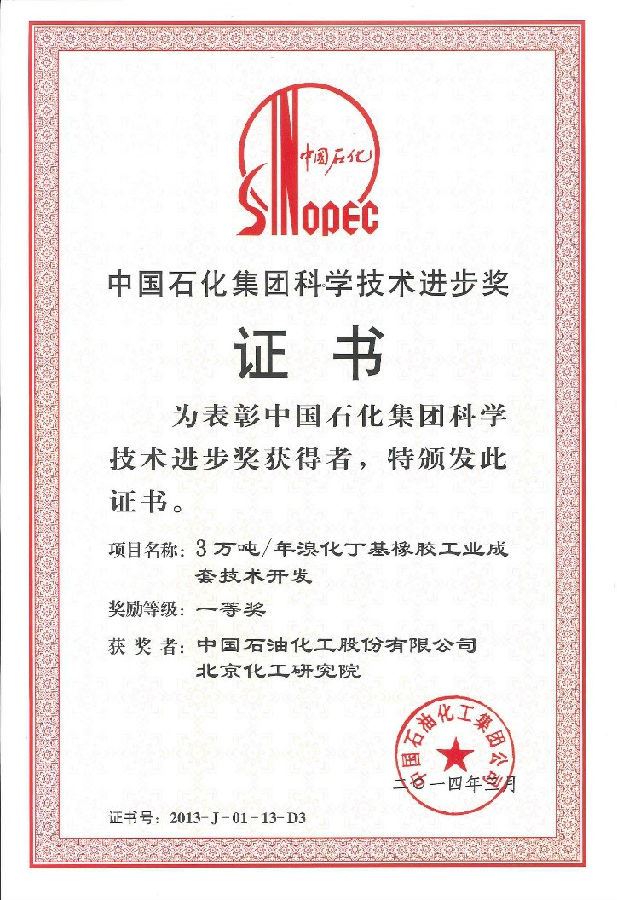

Project: 30kt/a BIIR industrial technology development

Award: Sinopec scientific and technological progress first prize in 2012

Project introduction:

BIIR, modified from IIR, is the preferred material for tire inner liner and medical rubber stopper, which maintains as excellent air impermeability as IIR but improves curving rate and adhesive property to a great extent. For all the time, the production technique of HIIR was owned without transfer by ExxonMobil and Lanxess, which accounted for about 80% of global production. With domestic demand totally dependent on imports HIIR price stayed high until domestic plant put into production.

Yanshan branch of BRICI has been committed to technology development of IIR/BIIR for many years, from basic and bench scale research to engineering enlargement and industrialization.

The first set of BIIR process unites of 30 kt/a with Sinopec independent technology was completed and put into operation in Oct. 2010, which filled the domestic blank and ended the foreign monopoly. Two brands for common use of BIIR 2032 and 2046 made by Sinopec have been put into market and that for special purpose is still in developing.

Table The properties of Sinopec BIIR

items | units | BIIR2032 | BIIR2046 |

Mooney Viscosity[ML(1+8)125℃] | Pts | 32±5 | 46±5 |

Combined bromine | mol% | 1.05±0.1 | 1.05±0.1 |

Volatile Matter | wt% | ≤0.7 | ≤0.7 |

Antiager | wt% | 0.02min | 0.02min |

Stabilizer | wt% | 1.3±0.3 | 1.3±0.3 |

MH | dN.M | 37.0±7.0 | 43±5.0 |

ML | dN.M | 14.0±5.0 | 17±5.0 |

ts2 | Min | 4.0±2.5 | 4.0±2.5 |

Tc-90 | Min | 12.0±4.5 | 12.0±4.5 |

Colors | White | White |